Omnisys has an installed industrial capacity to handle the electronic and mechanical manufacturing of its products with solid processes and highly qualified professionals.

Services

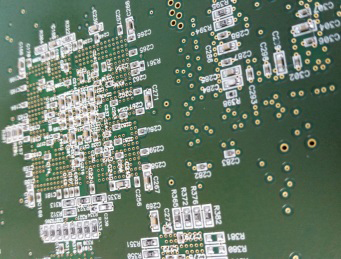

- SMT Line - Automatic Production of Electronic Boards

-

Omnisys has an automatic electronic board assembly line capable of mounting over 18,000 components per hour for Lead Free and SnPb assemblies.

The SMT Line consists of an automatic printer, a pick and place machine, an optical inspection device (AOI), a reflow oven with nine convection zones (top and bottom) and a cooling zone. The final part of the assembly line has an electronic board-cleaning machine and an ion contamination meter.

This assembly line has undergone a rigorous certification process to ensure the quality required for Omnisys-produced world-class products.

Checkout our SMT video clicking here.

- Assembly line and manual complement

-

To meet electronic and electromechanical assembly and complementation for PTH components, Omnisys' industrial area has manual mounting posts that meet ESD standards. All assembly documentation is available online by the Quality Department through the Electronic Document Management (GED), thus ensuring assembly control with the updated documentation at each workstation.

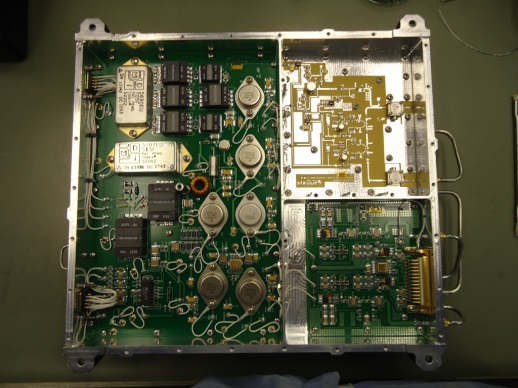

- Electronic Integration

-

The company has integration centers prepared with adequate equipment and qualified professionals for the final integration of its products and preparation for the factory acceptance tests.

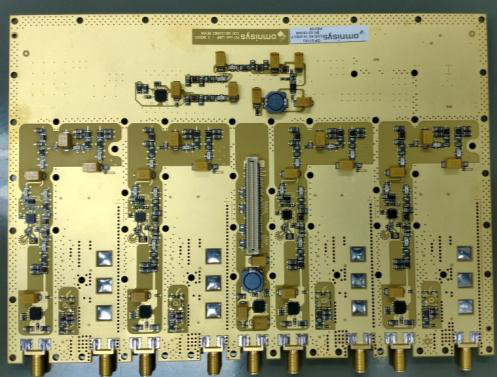

- Clean Room Class 100,000 (ISO Level 8)

-

Omnisys has a fully qualified class 100,000 clean room for mounting and testing of electronic boards and modules, as well as integration and testing of equipment and subsystems for space application. The sector consists of a manufacturing area and a test area with a climate chamber with an internal volume of 1m3, operating in a temperature range from -40°C to 180°C and humidity control from 20% to 95%.

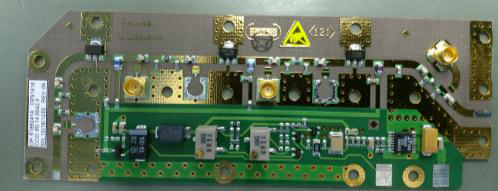

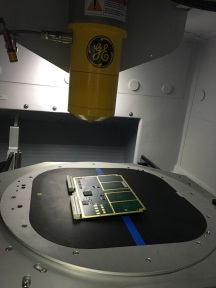

- BGA Repair Center

-

Omnisys has specific equipment for replacing BGA, QFN, µBGA / CSP, Flip Chip and other SMD components. This area operates both in the production of electronic boards and in support of the Service Center in repair of failed boards.

For complete validation of the replacement of components, the company has an X-ray inspection equipment, thus ensuring 100% reliability in repairs performed.

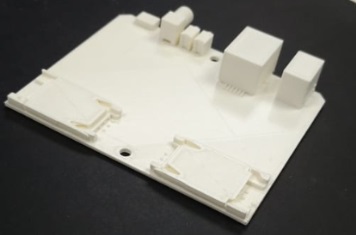

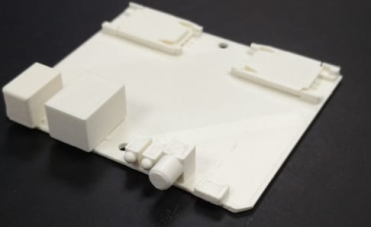

- Impressão 3D

-

A Omnisys conta com uma impressora 3D para fabricação de partes especificas de peças e modelos de validação de projeto, provendo suporte à Engenharia durante as fases de projeto.

- Mechanical Manufacturing

-

The company has a Mechanical Manufacturing Center that encompasses cutting and bending, boilermaking, abrasive blasting, painting, screen printing and machining.

- Boilermaking - Cutting and Bending

-

Cutting capacity: Sheet width 2040 mm; 3.5 mm thick carbon steel; 2.3 mm thick stainless steel and 5.0 mm thick aluminum.

Bending capacity: 1900 mm bending length; 3.5 mm bend thickness and 300 mm bend height.

- Boilermaking | Solder

-

The boilermaking has the capacity to perform TIG Welding aluminum, stainless and carbon steel with a team of welders certified by the standards ABNT and EN ISO 9606 (European).

- Boilermaking | NBR-6831/01 Glass Microsphere Abrasive Blasting

-

Abrasive blasting equipment removes surface contaminants and prepares parts for surface treatment or painting.

- Boilermaking | Painting

-

The sector has structure and capacity to carry out the painting works in dry painting booth for Epoxy or PU liquid paint with exhaust fan and carbon filter.

Screen printing (Epoxy) processes are also performed.

- CNC Machining Center

-

The Center has the ability to manufacture high precision CNC mechanical parts and use modeling and CAD (power shap and power mil) programs.